Cheap 4 Axis Robotic Arm Sheet Metal Press Automation Bionic Manipulator Hand

Basic Info.

| Model NO. | HC415 |

| Origin | China |

Product Description

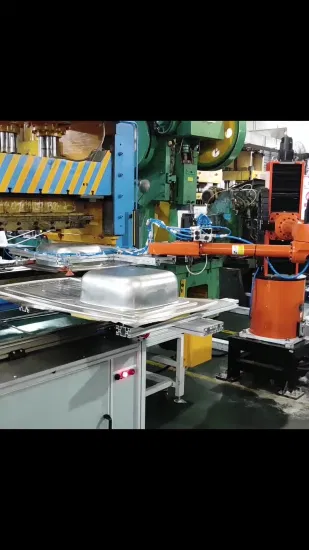

Product DescriptionHCNC stamping robot four-axis robotic arm for sheet metal press automation is a high-rigidity four-axis robot, which achieve low cost and high performance in the same level of payload of other robots. It is the best choice for the stamping and handling industry. HCNC HC415 robot's payload is up to 15kg, the range of motion is 1402mm.

Features- Designed especially for the stamping and loading industry

- High rigidity with cast iron material. The robot weighs 250kg which is stable and can adapt well

to the hard working condition of stamping industry. - Cycle life is up to ten years, brings high return on investment.

- High integration, built-in signal interface and air pipe interface

- Strong smoothness and the transition point pause time is close to zero

| Industrial robot | HSR-HC415 | |

| Degree of freedom | 4 | |

| specified load | 15Kg | |

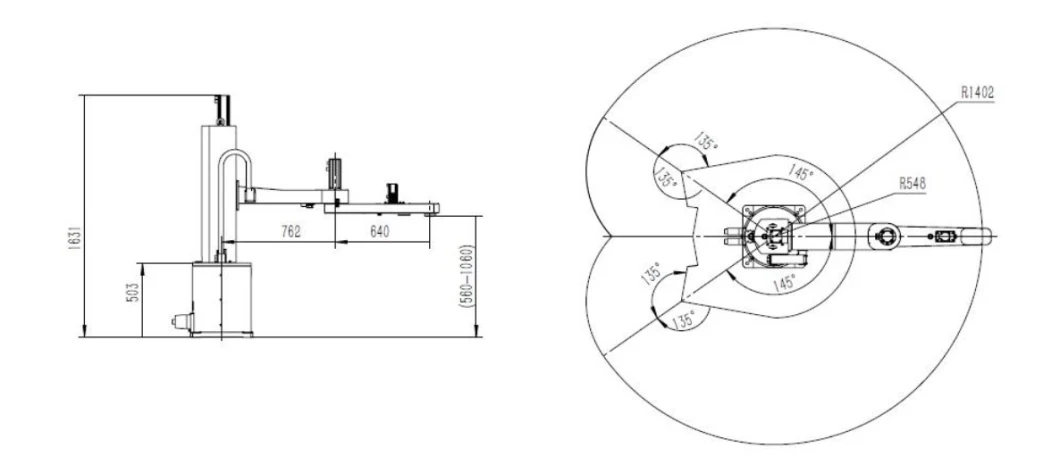

| Maximum working radius | 1402mm | |

| Repeatability | ±0.05mm | |

| Range of motion | J1 | ±145° |

| J2 | ±135° | |

| J3 | ±250mm | |

| J4 | ±180° | |

| Rated speed | J1 | 225°/s,3.93rad/s |

| J2 | 225°/s,3.93rad/s | |

| J3 | 500mm/s | |

| J4 | 180°/s,3.14rad/s | |

| Maximum speed | J1 | 300°/s,5.23rad/s |

| J2 | 375°/s,6.54rad/s | |

| J3 | 830mm/s | |

| J4 | 360°/s,6.28rad/s | |

| Allowable moment of inertia | J4 | 3kgm^2 |

| Allowable torque | J4 | 50N·m |

| Applicable environment | temperature | 0~45° |

| humidity | 20%~80% | |

| other | Avoid contact with flammable, explosive or corrosive gases and liquids. Keep away from electronic noise sources (plasma). | |

| Cable Length of Instructor | 8metre | |

| Body-cabinet connection length | 6metre | |

| I/O parameters | Digital:32 inputs, 31 outputs (one for control cabinet fault indicator output) | |

| battery capacity | 2.8kVA | |

| rated power | 2.2kW | |

| Rated voltage | Three phaseAC380V | |

| Rated current | 4A | |

| protection grade | IP54 | |

| Installation method | Ground installation | |

| Body weight | 250kg | |

| Control cabinet protection grade | IP53 | |

| Control cabinet size | 660(wide)×450(thick)×950(high)-vertical | |

| Control cabinet weight | 50Kg | |

Huashu Robot is one of those subsidiaries of HCNC. It focuses on the research and development, manufacturing, application and service of industrial robot products. It is the best engineering contractor for robot automation solutions and the best provider of intelligent manufacturing and overall solutions of smart factory. It has 9 subsidiaries in Foshan, Chongqing, Shenzhen, Dongguan, Ningbo, Suzhou, Quanzhou, Jiangyin, Nanning, and 4 research institutes in Foshan, Chongqing, Quanzhou, and Changzhou, covering major areas all around China. The annual production capacity is 10,000 sets of industrial robots.Huashu Robot fully implements the "PCLC" development strategy. At present, we have mastered 4 core key components of industrial robots, and have 6 series of more than 40 robots. They have continuously achieved breakthroughs in household appliances, electronics, hardware, automobile and motorcycle, kitchen and bathroom, shoemaking, lithium batteries, solar energy, and FMGG logistics. Our market influence has expanded rapidly, and they already have the ability to compete with famous international robots brands

FAQ

Q1:What's the material of your industrial robot?A1:The material of industrial robot is composed by Cast iron and cast aluminum. Q2: Your robot controller has input/ouput cababilities?A2:Yes, our robot controller has input/ouput cababilities.Q3: How to make program for you industrial robot?A3: There are two ways to make program for our robotic arm: a. For easy travel motion, we can use the handheld teach pendent to make the program. I attach the document of the teach pendent so that you can know more about it. b. For some complex motion, we can use the offline program software Interobot (developed by Huashu Robot), which can simulate the motion of the robot and make the programming easier.Q4: What kind of industrial robot you have?A4: We have industrial robot of 6 series with more than 40 models which can be used for picking up, welding, grinding and polishing, sorting, painting, injection applications, loading and unloading pieces for machine tool, etc.Q5: What's the delivery time of you product?A5: Our annual production capacity is 10,000 sets of robots. The concrete delivery period should be confirmed based on the number of orders.Q6: Why choose Huashu Robot?A6: Huashu Robot has more than 1500 technician dedicated in the research and development of its products. The core parts of industrial robot such as robotic controller, robot body, servo motor and servo drive are developed by ourselves, which can help our clients upgrade the system based on customers'needs. Besides of providing the robot, we can also give a complete solution, providing you with one-stop services.Q7: Do you have collaborative robot?A7: We already have collaborative robot which can remember the movement points by manually dragging the robotic arm, avoiding the complicated programming process. This collaborative robot can be used for medical treatment and welding application.